3D PRINTING SPECIAL MACHINES

INDUSTRIAL 3D PRINTER ADAPTED TO YOUR NEEDS

Want to integrate your 3D printing into your production line? Or need custom dimensions? You’ve found the right partner!

Additive material extrusion is increasingly being integrated into production for the manufacture of small series or high variation in series quality. Connection to upstream and downstream processes and their systems requires specialist knowledge in both automation and design. Control and safety technology requirements are also on the increase. With 40 years of experience in special machine construction and many years of expertise in industrial 3D printing and materials technology, we ensure robust and reliable 3D printing solutions.

BENEFITS OF

HAGE3D 3D SPECIAL PRINTING MACHINES

- 40 years of experience in special machine construction

- Exclusive use of industrial components

- Exclusive use of industrial machine controls

- Years of experience in industrial 3D printing

- Large, closed and temperature-controlled build chambers

- In-house material and application centre for process reliability

- Modular machine system thanks to exchangeable print heads

- Long-term 24/7 operation thanks to robust mechanical engineering

- Free choice of materials – no manufacturer ties

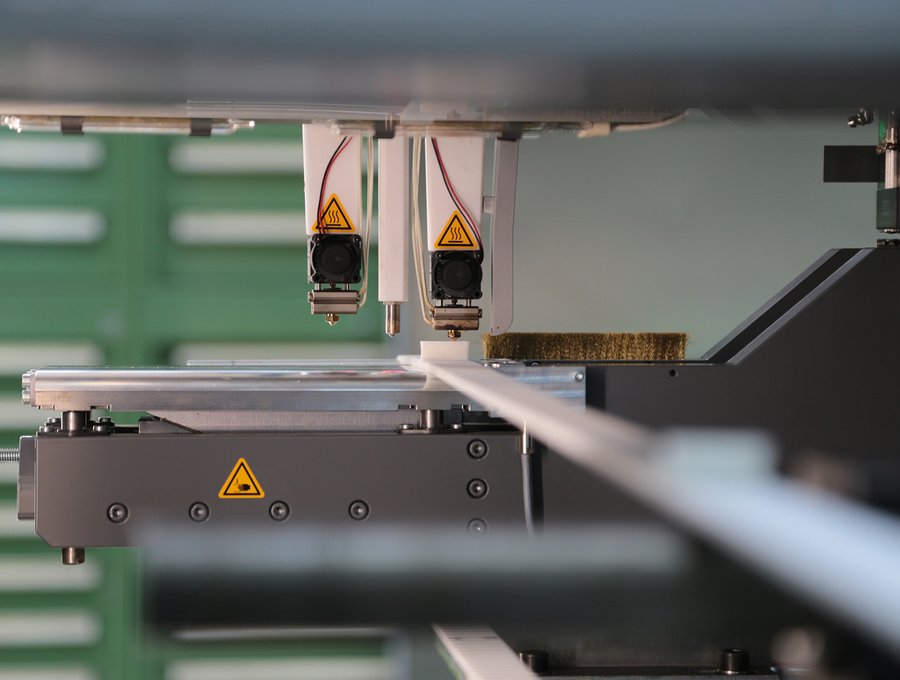

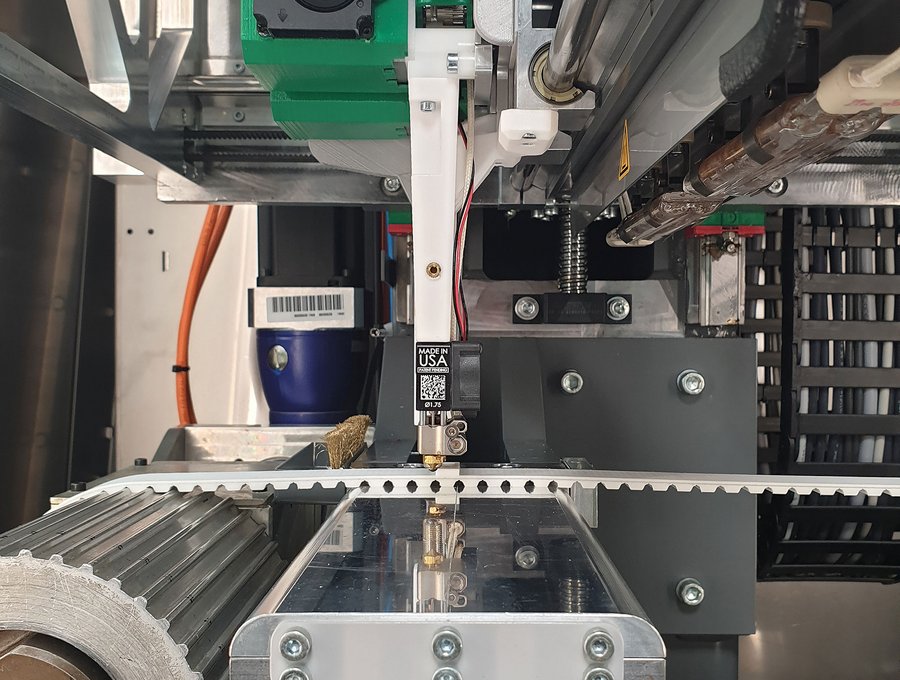

MEX PROLINE

3D printing in series production and cyclical production? With the PROLine, HAGE3D is pleased to be able to offer a solution that allows printing on an endless conveyor. It enables printing directly onto plastic parts, textile or other materials that are part of your conventional production process. The HAGE3D Proline is entirely value-adding when used as a production line in additive cyclical and series manufacturing.

MECHANICAL ENGINEERING

Build chamber (YZ): | Y: to 300 mm |

Build chamber (X): | Endless conveyor |

Heatable build chamber: | Yes, to 50 °C |

Closed build chamber: | Delivery standard |

Print bed: | Heated, as required |

Calibration: | Optional automatic print bed survey before each print |

Drive technology: | Closed-loop technology for accurate step positioning without step losses |

Positioning accuracy: | < 0.1 mm |

Safety circuit: | Yes, 24/7 operation permissible |

CUSTOMISING

Mechanical link to customer production/conveyor | Yes |

Control interface | Yes |

Integration with customer’s mechanical and control system to create a complete solution | Fully integrated solution |

Control technology interface | Based on HAGE3D’s own control with defined modifications and corresponding interface to the customer’s system |

PRINT HEAD

Print head: | Air-cooled print head with free stroke of the inactive extruder |

Filament feed: | Synchronised counter-running profile wheels for reliable feed |

Component cooling: | High-performance, targeted cooling up to 4.8 m³/h |

Nozzle diameter: | 0.2 mm to 1.0 mm (0.4 mm standard) |

Layer thickness: | from 0.05 mm |

Printing speed: | to 90 mm/s (depending on geometry and material) |

Build-up rate: | to 150 g/h (depending on geometry and material) |

Print temperature: | to 300 °C |

USER CONVENIENCE

Standalone printing: | Via USB |

Network integration: | Ethernet connection |

Remote maintenance: | Yes |

Pause printing: | Smart ‘stop and go’ function |

Slicing software: | Simplify3D (delivery standard) |

Machine control: | Industrial control (HAGE3D) |

Operating display: | LED + 7” touchscreen |

Filament withdrawal: | Empty level monitoring |

Override function: | In real time |

User level: | Multi-level |

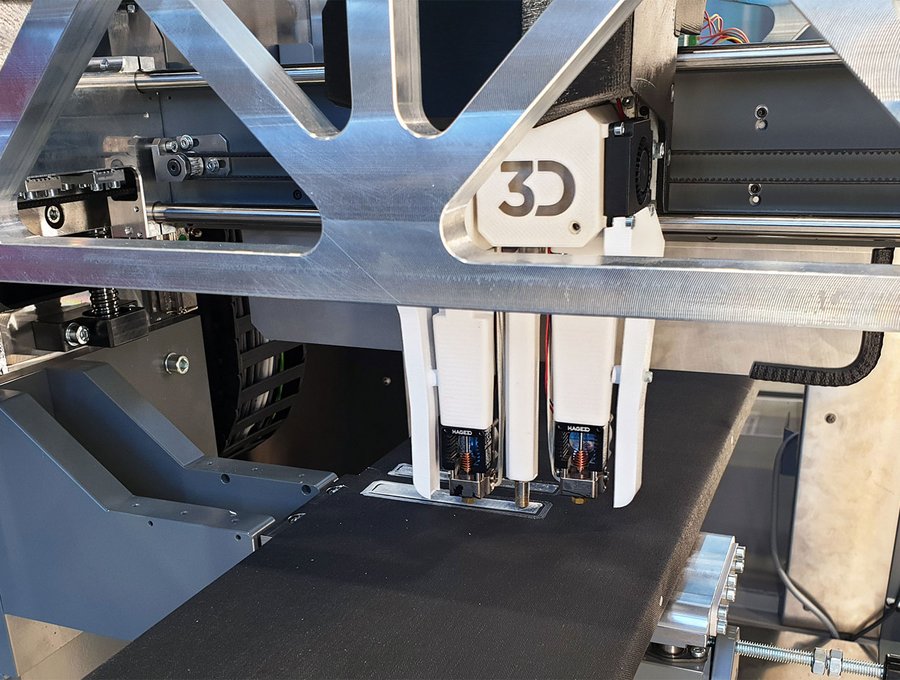

HAGE3D 175 CONVERTIBLE

The HAGE3D 175 Convertible is a comprehensive platform concept allowing customers to adapt their use to their needs. It takes just a few minutes to switch from three-axis printing to five-axis printing, and vice versa. The machine also allows the user to switch between filament print heads and a granulate print head.

MECHANICAL ENGINEERING

Three-axis build chamber (XYZ): | 1200 mm x 1200 mm x 1100 mm |

Five-axis construction space (XYZ): | 500 mm x 500 mm x 500 mm |

Heatable build chamber: | to 80 °C |

Lighting: | Interior LED lighting |

Heatable print bed: | to 140 °C |

Print bed calibration: | Automatic via multi-point topographic survey |

Drive technology: | Water-cooled servo motors with absolute value encoder |

Positioning accuracy (XY): | < 0.03 mm |

Movement speed: | XY 300 mm/s, Z 400 mm/min |

Safety circuit: | Yes, 24/7 operation permissible |

INSTALLATION INFORMATION

Power supply: | 400 V/230 V |

External dimensions (XYZ): | 2550 mm x 2450 mm x 2350 mm |

Weight: | approx. 2500 kg |

PRINT HEAD

Print head: | Five-axis single print head, Standard-DSD, Multi-DSD, PEX |

Component cooling: | High-performance, targeted air cooling up to 4.8 m³/h |

Nozzle diameter: | 0.2 mm to 1.0 mm (standard: 0.4 mm) |

Printing speed: | to 250 mm/s (depending on geometry and material) |

Build-up rate: | to 600 g/h (PEX, depending on geometry and material) |

Print temperature: | to 500 °C (DSD) |

USER CONVENIENCE

Standalone printing: | USB/network |

Network integration: | Ethernet connection |

Remote maintenance: | Yes |

Pause printing: | Smart ‘stop and go’ function |

Slicing software: | Siemens NX Multi-Axis Deposition |

Print control: | Siemens Sinumerik 840D sl |

Operating display: | LED + 18.5” touchscreen |

Filament stock: | Empty level monitoring |

Override function: | In real time |

User level: | Multi-level |