HAGE3D PRINT HEAD

TECHNOLOGy

In order to adapt the 3D printer to your needs to the fullest extent possible, HAGE3D has a number of print head technologies in its portfolio. The MEX modular concept allows print heads to be exchanged quickly and easily and in so doing, significantly increases the flexibility of production. With our modular concept, you use a HAGE3D basic machine and then select the most suitable print head according to your use. This enables optimal adaptation to the material’s basic form (granulate, paste, fluid, filament) and/or to the print job (standard components, hybrid components, large components, thermoset components, elastomer components).

HAGE3D print heads are characterised by the highest industry standards for reliable and accurate printing results.

DSD

The compact and lightweight DSD (Direct Synchronised Drive) filament print head can be integrated into all HAGE3D printers. The print head processes a wide range of filaments with accuracy and reliability. The DSD is modular in construction and can be operated with a variety of cooling, filament drive and hot end concepts.

New cooling management for increased process reliability

Filament extrusion requires thermal decoupling of filament supply, melting area and heated build chamber. On the DSD print head, this is achieved either with air cooling, including POM insulation, or with specially designed water cooling. We use the ‘air cooler’ in our smaller HAGE3D machines, where it is more beneficial for the print head to be as light as possible. The ‘water cooler’ is used in larger and high-temperature HAGE3D machines, ensuring thermal protection of the filament and print head.

Reliable and flexible filament supply thanks to an innovative drive concept

Different filament materials require different drive concepts. The DSD print head uses profiled drives (form fit) for thermoplastics and synchronised rubberised drives (friction fit) for very soft or highly filled filaments. The drive units are easy to change. Additionally, a low-loss and partly spring-mounted transmission system increases the efficiency of conveyance between the stepper motor and filament drive. Filament slippage, filament wear or motor step losses at high printing speeds are now very much a thing of the past. Extremely short and friction-free filament paths ensure a kink-free filament feed, even when the filaments are very soft (< Shore A 80).

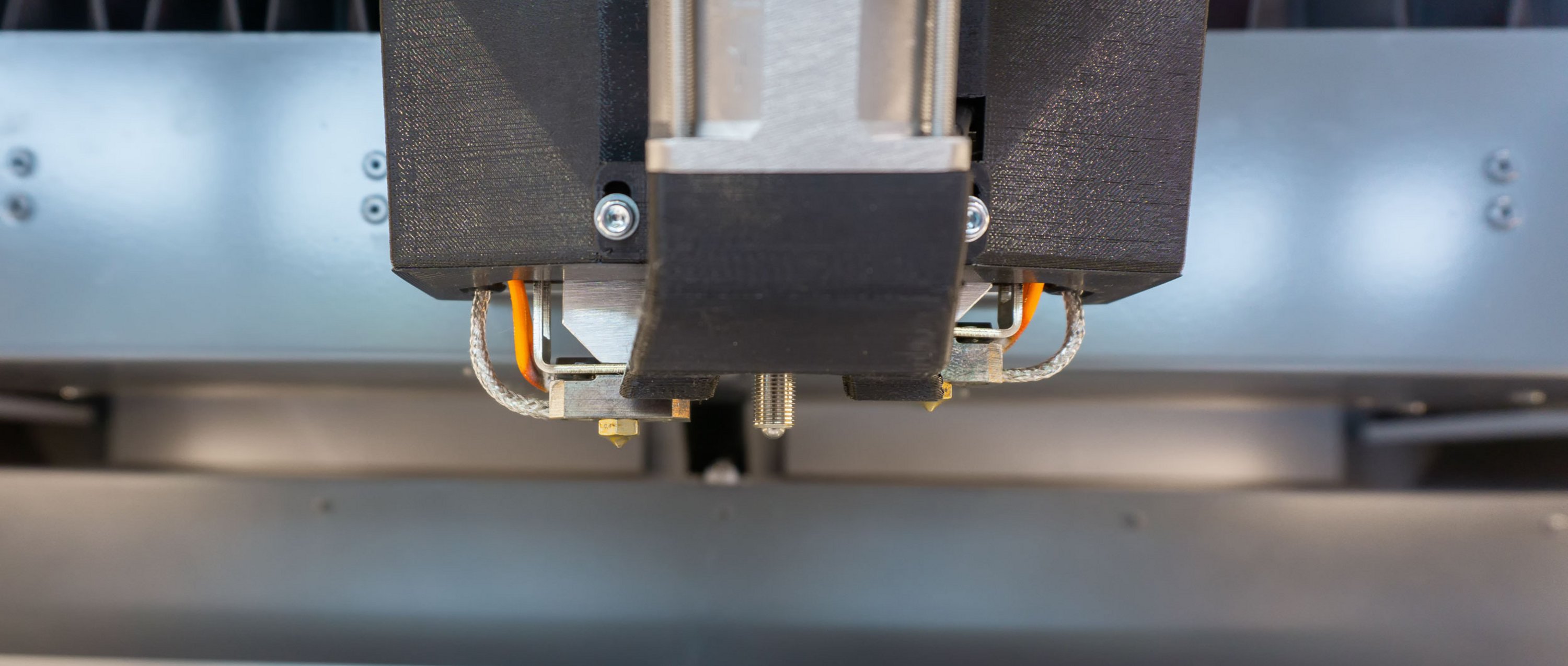

Robust free stroke (nozzle switch) and automatic nozzle calibration

We supply the DSD print head with two extrusion units as standard. A servo stroke allows independent and rapid switching of the extruders for accurate dual printing. A mechanical print probe system ensures reliable head referencing and automatic nozzle length calibration in the hundredths range. The print probe system is also used for topographical correction of the print bed. In contrast to optical or magnetic systems, this can be carried out independently of the print bed material.

Maximum feed rate and precision

Working with the leading hot end technology provider, HAGE3D provides precise hot ends with a counterpressure-minimised melting zone. This ensures accurate multi-component printing without melt dripping. Alternatively, power hot ends offer performance-optimised, long melt zones for high extrusion volumes of up to 300 g/h. The hot ends are fully modular and easy to assemble. The full-metal hot ends have a new bimetallic thermal barrier that combines wafer-thin steel for stability and thermally conductive copper for the thermal connection. This allows for reliable processing of challenging materials such as TPU and PEEK. The highly thermally conductive heating block is virtually creepage-free, even at extrusion temperatures that exceed 500 °C. The carefully considered mechanical design enables safe and easy changes of nozzles, heater cartridges and thermistors. For HAGE3D, a high-quality nozzle system is important. Working with a leading nozzle manufacturer, we offer DSD-compatible, high-quality tool steel nozzles with optimised thermal conductivity. It is possible to print unfilled, highly filled and abrasive systems with only one nozzle without difficulty. Disruptive material deposits in the nozzle are now a thing of the past thanks to the low sliding friction coefficient.

- Cooling concept: water-cooled or air-cooled

- Extrusion temperature: up to 450 °C

- Maximum delivery rate: 300 g/h

- Filament diameter: 1.75 mm

- Nozzle diameter: 0.3 mm to 1.0 mm

- Filament feed: form fit or friction fit

- Extrusion units/print head: 2 with servo switch

AVAILABLE FOR THE FOLLOWING MACHINES

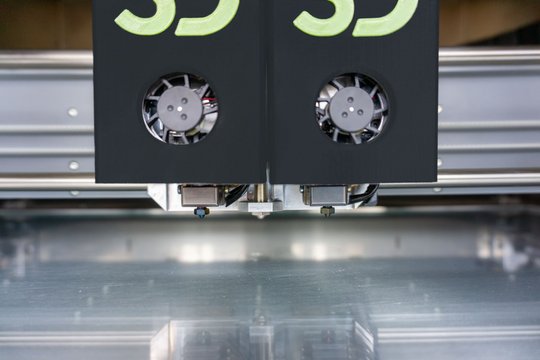

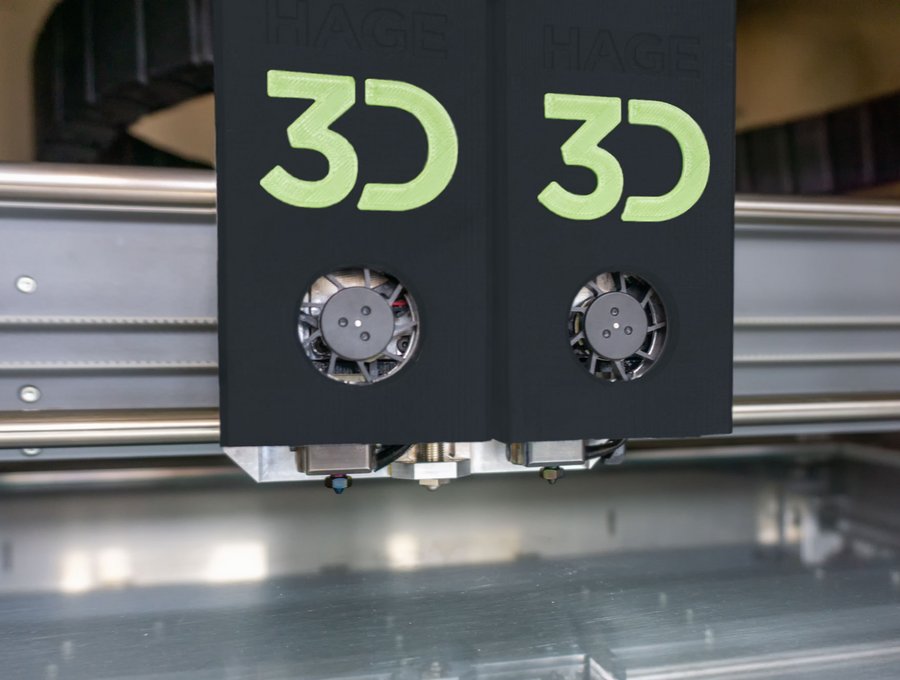

MULTI-DSD

The HAGE3D Multi-DSD has up to four extruders. By contrast, the DSD standard print head has two extruders. The Multi-DSD allows four different materials to be processed in a single print. A component that is a combination of hard/soft components, distinguishable colour identification and solubility support is just one example of multi-material technology.

Multiple materials in a single print: a real benefit of additive material extrusion

The option to process more than two materials in a single component opens up entirely new prospects in additive manufacturing, including:

- Components with four colours

- ‘Continuous printing’ with four large spools (backup function x 4)

- A combination of different material functions, such as hard/soft transitions.

The combination of materials is one of the strengths of additive material extrusion and makes the process fundamentally different to mono-material techniques such as laser melting/laser sintering and stereolithography.

Cooling concept: water-cooled or air-cooled

Extrusion temperature: to 450 °C

Maximum delivery rate: 300 g/h

Filament diameter: 1.75 mm

Nozzle diameter: 0.3 mm to 1.0 mm

Filament feed: form fit or friction fit

Extrusion units/print head: 4 with servo switch

AVAILABLE FOR THE FOLLOWING MACHINES

The HAGE3D PEX pellet extruder combines the benefits of high melt output with a significant reduction in material costs, achieved thanks to the use of cost-efficient plastic pellets. This facilitates rapid, cost-efficient printing of large components.

PELLETEXTRUDER

Rapid and cost-efficient large print with pellets

Filament extrusion has benefits in precise, high-resolution additive material extrusion - although, at the same time, this is also a drawback. When printing very large components, the purchase of filament can quickly exceed the budget. Non-filamentable materials such as highly filled plastics also pose a problem. A good enough reason for us to offer a PEX pellet extruder. This special print head works directly with commercially available plastic pellets. PEX scores particularly highly with large components where unit costs need to be minimised and manufacturing times need to be shortened. It is also indispensable when working with plastics where filamentation is not possible.

- Cooling concept: water-cooled

- Extrusion temperature: up to 300 °C

- Maximum delivery rate: 600 g/h

- Granulate form: Standard granulate

- Nozzle diameter: 0.6 mm/1.0 mm (larger diameters on request)

- Pellet feed: screw extruder

- Extrusion units/print head: 1

VERFÜGBAR FÜR FOLGENDE MASCHINEN

SPECIAL HEADS

3D printing users typically use filaments or pellets semi-finished products. But, what happens if you want to process pastes, resins, concrete or continuous fibres? HAGE3D offers a number of special print head solutions for this very purpose.

HAGE3D special print head solutions extrude the most challenging of materials

HAGE3D has acquired extensive knowledge in the development and implementation of special print heads through a range of cooperation agreements with research partners. Whether in cold extrusion (pastes, resins, concrete) or in hot extrusion (continuous fibre composites), HAGE3D has the solution for every extrusion-capable material.